Anodizzazione alluminio

The treatments are carried out in full compliance with the UNI 10681 standard to obtain a degree of thickness equal to 10/15 microns up to a maximum of 25/30 microns at the customer’s request.

To improve the aesthetic appearance, to increase surface hardness, increase abrasion resistance, to provide moderate thermal insulation, to increase resistance to corrosion in the marine field and to improve other characteristics, such as gluing.

For small mechanical parts we offer the ZERO DEFECTS finish, comparable to ZERO CHEMICAL, and recommended for tolerated pieces (eg: with holes in H7).

In the food sector, upon request, we issue MOCA certification.

WHAT WE OFFER

Satinizing

Mechanical brushing

Scotch-Brite brushing

PRODUCTS

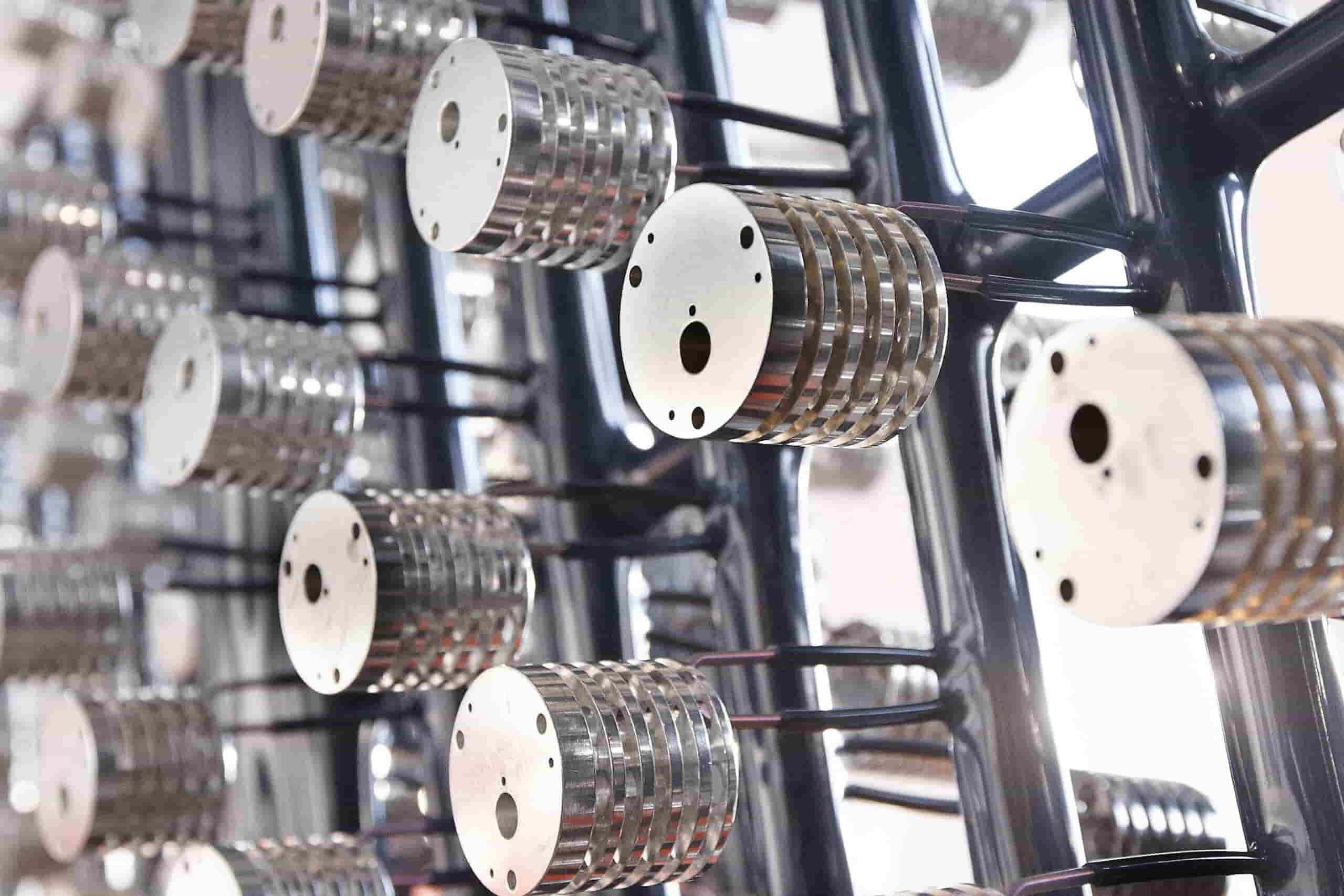

Flanges – Valves

Casting/Die-Casting

Cylinders – Drive Shafts

Engines Components

Different small parts

Plates and sheets

COLORS

Silver

Black

Electrocolor

Mechanical brushing

In anodizing, trim surfaces are of great decorative importance.

Mechanical processes can be combined with chemical ones to get the best finishes possible

To this end, we have 4 different types of brushing machines:

- Manual band cleaners suitable for medium and large plates for a deep brushing

- Brush cleaning for details and small accessories

- Automatic cleaning machine for surface finishing and for an aesthetic finish of medium and large sized material and for all those details with tolerance problems

Packaging and warehouse

The packaging of the anodized material is a fundamental part, which is designed and customized, as well as the different types of materials being processed.

An important role is provided by logistic dept.: indeed the company has its own means of transportation and delivery personnel in order to minimize delays in both collections and delivery times.